140 Years in the Making

Making the industry’s best malts and brewing ingredients takes time. In our case…about 140 years. That’s when the Briess malting tradition began, in 1876 when Ignatius Briess—a grain exchanger—began malting barley grown in the fertile Moravian valleys of his homeland Czechoslovakia.

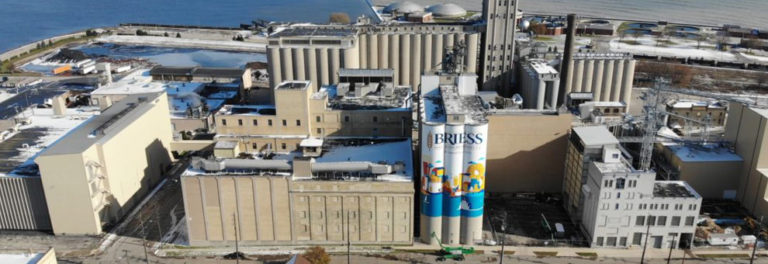

Little did Ignatius know that his handcrafted traditions would cross the Atlantic to a small town in Wisconsin…to be handed down to generations of family members just as obsessed with quality malt as he was.

Today, Briess Malt & Ingredients Co. is a recognized leader in developing and producing handcrafted specialty malts for the American Craft Beer industry. Producing more styles of malt than any other malting company in the world, Briess sets the benchmark for unique flavor, color, and performance in handcrafted specialty malts.

If you have time, check out our history. Better yet, check out our products. We know you’ll like them!

Mission Statement

For more than 135 years Briess has built its business on the tried ‘n’ true principle that we succeed only when our customers do. That’s why we won’t settle for just supplying the finest specialty malts available. Because we’re passionate about your success, we also supply innovative solutions and services to help you jump over daily hurdles, solve problems, and develop innovative efficiencies. This is so fundamental to us that we’ve made it our Mission Statement:

“Your partner for success - providing all-natural, value-added ingredients, solutions & service.”

We believe that partnering with you is the best way to help you succeed. By getting close to you and your operations, our knowledgeable and friendly sales/technical team can help you troubleshoot problems, adjust to different crop years, formulate recipes, prepare cost-effective malt purchasing programs, recommend operating efficiencies and simply brew the best beer possible in the most efficient manner.