For centuries, malt has served as the foundational element of beer. Its origination as a process to liberate soluble components of grains and pulses and generate enzymes to aid in the fermentation process opened the door to a plethora of applications. From beer, bread, and whiskey to coffee replacement and malt extracts, the range represented the beginning of standardized malt production.

When malting was industrialized and technological advances allowed for increased batch sizes in the late 1800s, the focus on which variables needed to be controlled in the process to produce consistent malted batches started to be identified. As improvements related to equipment and process efficiency were discovered and implemented, attention turned back to the barley itself.

As regulations shifted and prohibition ended, investment in barley breeding and development began as the industry’s maltsters and end users aligned to collaborate on creating agronomic and quality targets to better educate those looking to grow barley and guarantee its economic feasibility and quality acceptance.

From the formation of these industry organizations came standards that are continuously evolving and defined by industry leaders partnering with academic research and barley breeding programs to strengthen the value and resiliency of malting barley. Malting barley requires more stringent growing requirements and higher quality standards than barley grown for feed or food use. This differentiation is made in the breeding and acceptance criteria defined for malting barley.

What is the role of the maltster?

Malt serves several key roles in beer design: function, flavor, and nutrients. The maltster is responsible for creating a system that delivers each of these characteristics consistently. One of the primary means is through intentional barley varietal selection. A maltster’s selection is weighed on several factors, including customer demand, product malting targets, and sourcing regions.

Barley Traits Review

There are a few general differences to point out as part of the understanding of malting barley:

2 Row vs. 6 Row Barley

6 Row (Top Image)

- High Protein

- High Enzyme Potential

- Lower Extract

2 Row (Bottom image)

- Low Protein

- Moderate Enzyme Potential

- Higher Extract

Montana State University

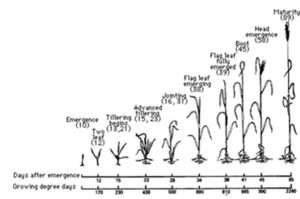

Spring vs. Winter Barley

Spring Barley

- Shorter Growth Cycle

- Varied Dormancy

- Later Harvest

- Yield Advances with Breeding

Winter Barley

- Requires Vernalization

- Higher Dormancy

- Yield Advantages

- Less Disease

- Earlier Harvest

- Climate Adaptation is Key

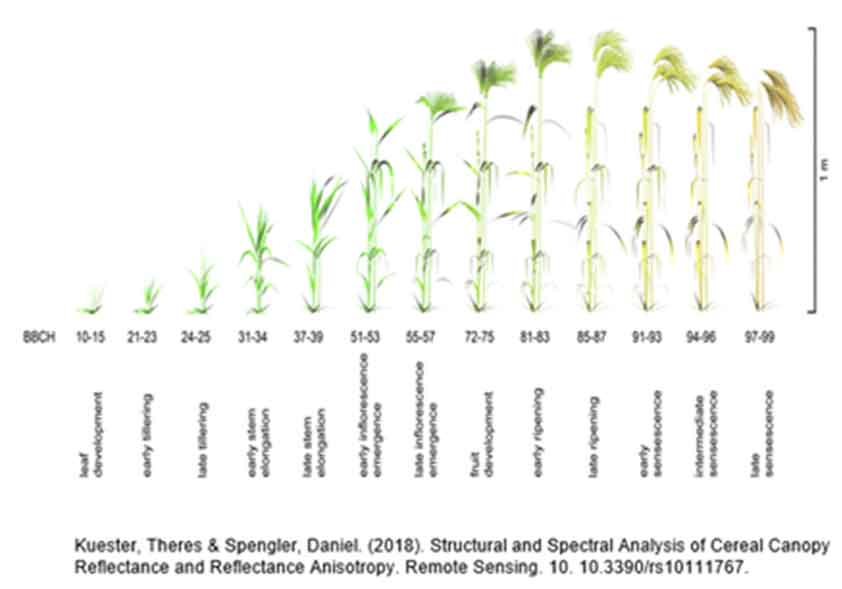

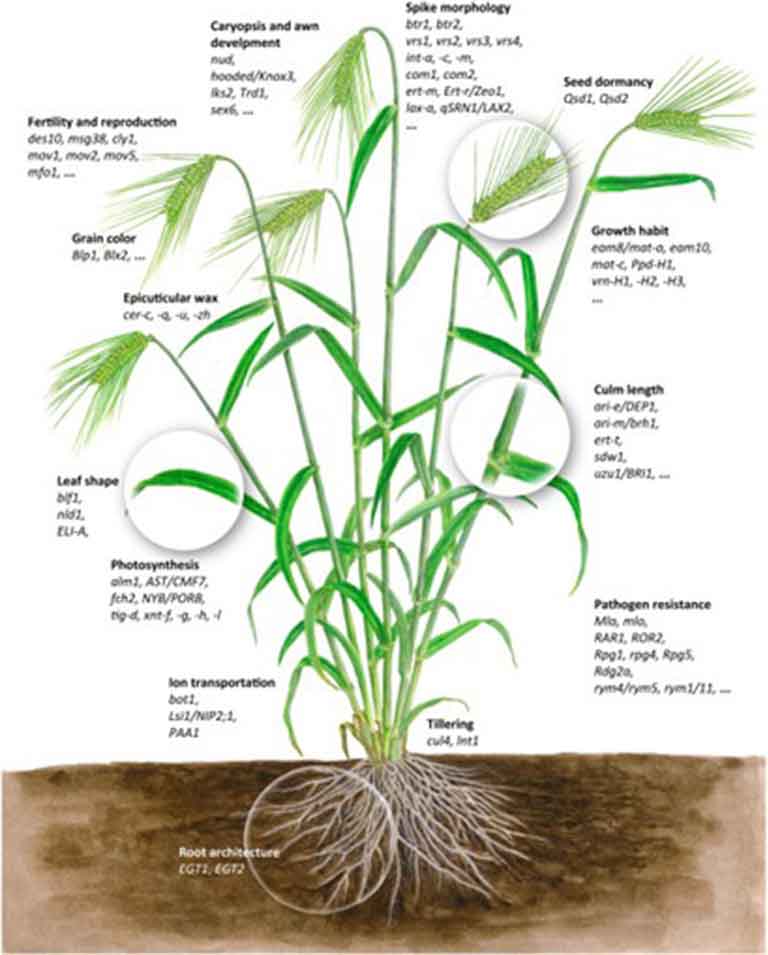

Barley genetics provides two different outcomes during the life cycle of the plant. During the growth cycle, it displays responses to the environment it is in. During harvest and use, it displays other traits because of its environmental response.

Photo Credit: American Malting Barley Association

The breeding process involves traditional cross-breeding techniques to select for the following phenotypic characteristics:

- Yield

- Weather Adaptation

- Stand and Height

- Disease Resistance

- Dormancy

- Malt Quality Parameters

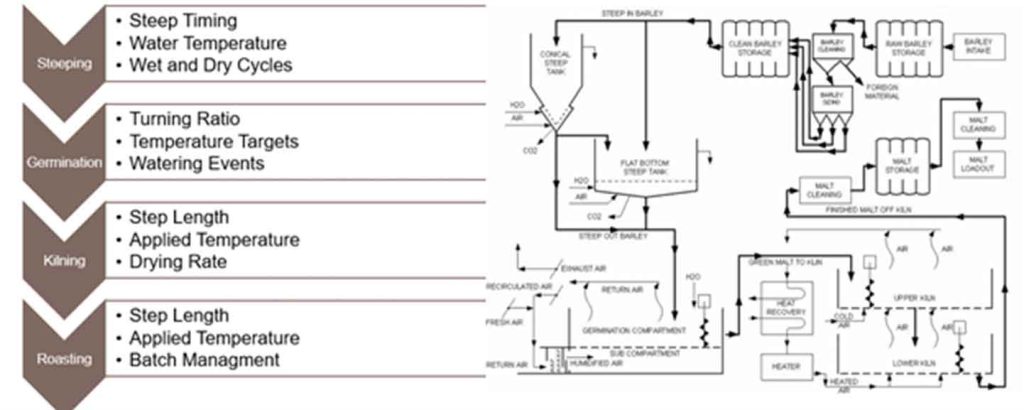

After harvest and quality acceptance, the maltster then evaluates differences in that variety from crop year impacts and growing region impacts. The process involves both small-scale pilot malting as well as commercial batches to verify scale. Malthouse performance is evaluated for the following parameters:

- Water Uptake Rate

- Germinative Energy and Capacity

- Color Formation Rate

- Enzyme Levels

- Modification Rate and Measurements – Friability, Viscosity, Beta Glucan

- Husk Retention

To adjust these parameters, the following process values are evaluated:

How Does Variety Approval Work?

Which varieties to plant is a partnership between the end user and the grower. There needs to be mutual benefit to the agronomic performance, acceptance, and malt performance of that variety on a consistent basis. The process of new variety approval is lengthy due to the use of traditional breeding techniques and growth cycles. In the US, there are public universities, end users, and private breeding programs that have research and breeding programs to continue to improve the performance, economics, and acceptance of malting barley.

In North America, there are two industry-led organizations that help align growers, breeders, and end users to a set of standards used to judge line advancement.

Every year, a well-rounded technical committee evaluates all the agronomic and quality parameters of newly available lines. The evaluation includes disease resistance, yield, weather adaptation, and malt quality parameter testing. The data collected for each line is combined into a single report and provided a rating. If the rating is deemed acceptable, the line can move on to the next phase of testing. The process moves forward through plant-scale trials, where it can then be made available to the public.

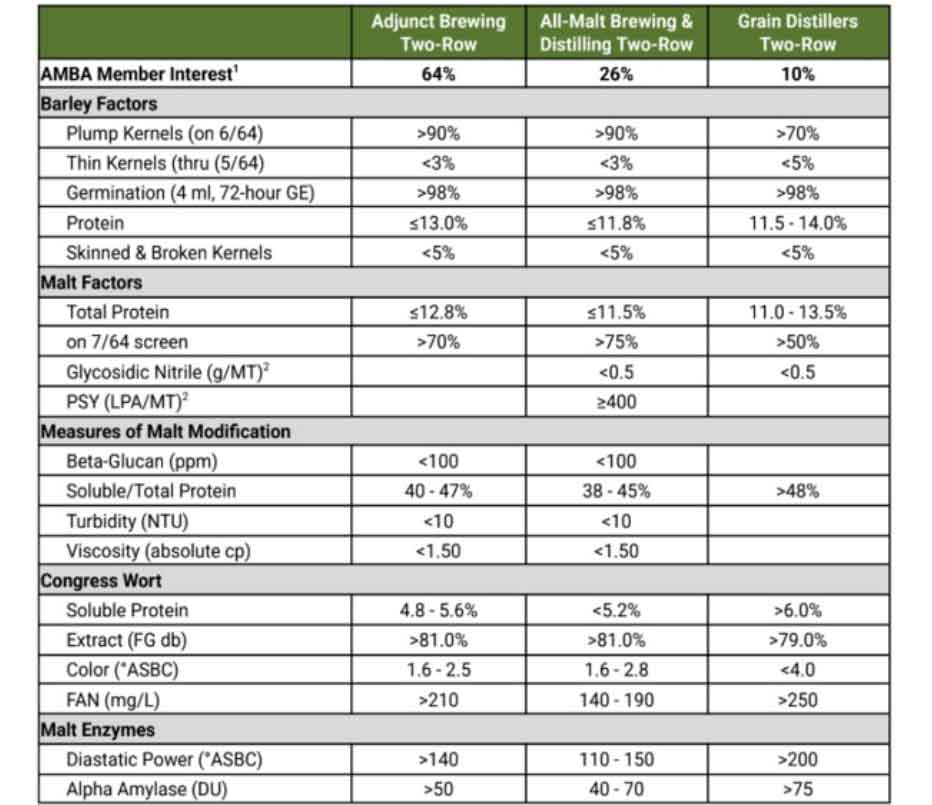

- Desired attributes are dependent on end-use applications

- Barley should mature rapidly, break dormancy quickly, and germinate uniformly

- Malting barley should exhibit even modification in a conventional 4-day malting schedule

Overall, the process for variety development and evaluation is lengthy and complex. However, the continued efforts over the last 100 years to improve malting barley have shown to be successful, allowing for greater yields on less acres, and reduction in rejections. Continued support of the advancement of malting barley helps ensure stability and consistency across the value chain. Briess conducts ongoing variety evaluation trials to ensure proper varietal alignment and performance through barley plot trials and pilot evaluation. We look to constantly evolve with our end-use needs and assess new and innovative varieties.