This year for HOMEBREW CON 2016, I submitted a poster on the Specialty Malt Acidity, which will be presented Friday, June 10: 12:30 pm – 2:00 pm at the Social Club of the Homebrew Expo.

Homebrewers sometimes overlook acidity, but it is a factor that can make the difference in a successful finished product or dumping your brew down the drain. It affects most of the processes in brewing (see abstract).

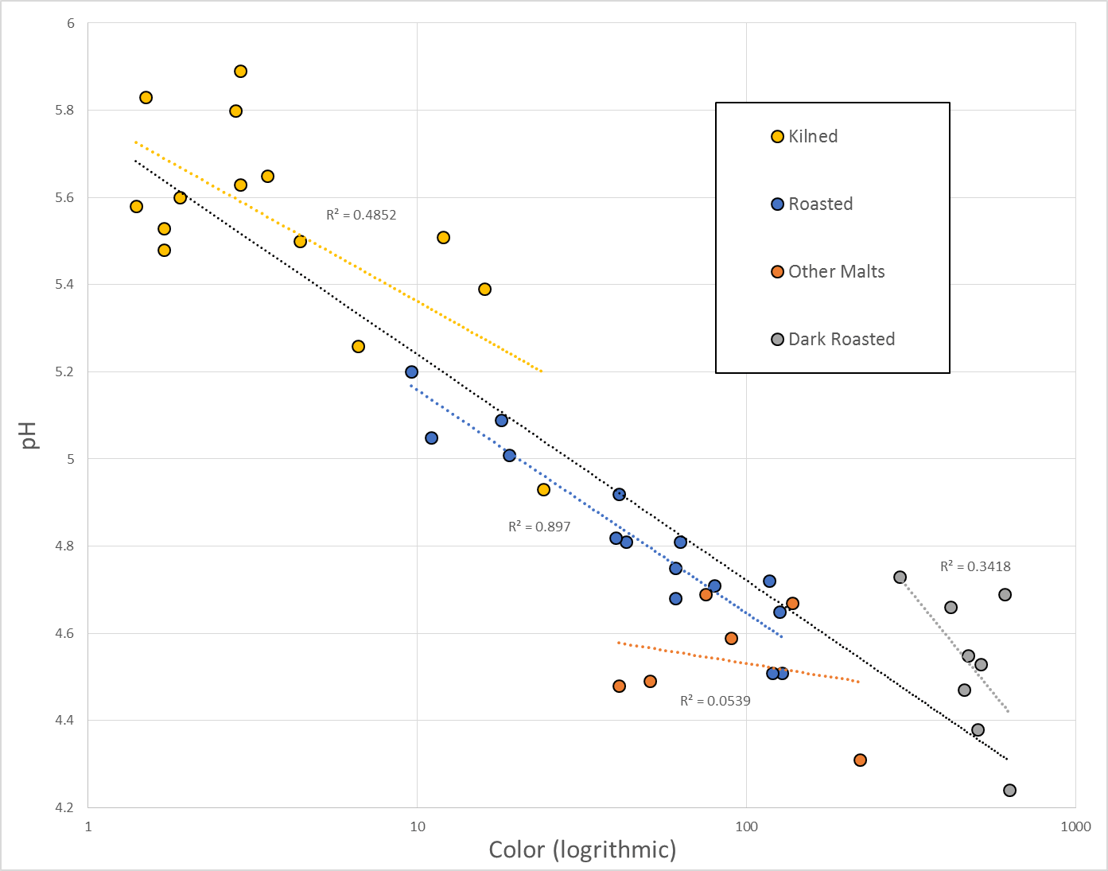

We looked at the relationship between finished color and acidity, and some of the factors that might affect that.

- Malt color in relation to pH

- Malt color in relation to titratable acidity (TA)

- How different production methods (ex: kiln vs. roasting) result in different pH/TA values and show varying degrees in the strength of the color/acidity relationship.

- How using different barley varieties (ex: Conrad vs. Conlon vs. Copeland) for the same finished product might result in differences in pH/TA

- How producing the same product at different locations (ex: Waterloo and Chilton) might result in differences in pH/TA

Abstract

Mash pH is a factor that influences enzyme activity, yeast health, solubility of compounds, clarity and the flavor of finished beer. Historically, in certain beer styles, the mash pH was sometimes manipulated by adjusting the grain bill with specialty malts of varying colors and acidities to achieve a desired target pH. We investigated numerous factors affecting titratable acidity of specialty malts including: production method, resulting malt color, barley variety and malting location. Our study evaluated the relative importance of these factors and their relationship to mash pH for a variety of samples with the aim of giving brewers a better quantitative feel for the effect specific malt types can have on mash pH. A strong relationship between mash pH and measured malt color was found. Barley variety and malting location showed a smaller and more variable effect.

*spoiler alert* haha

Conclusions

As color increases, pH decreases. As color increases, titratable acidity increases at different rates specific to the production method. Production method has the greatest effect on pH and titratable acidity, whereas barley variety and production location have a minor, more variable effects.