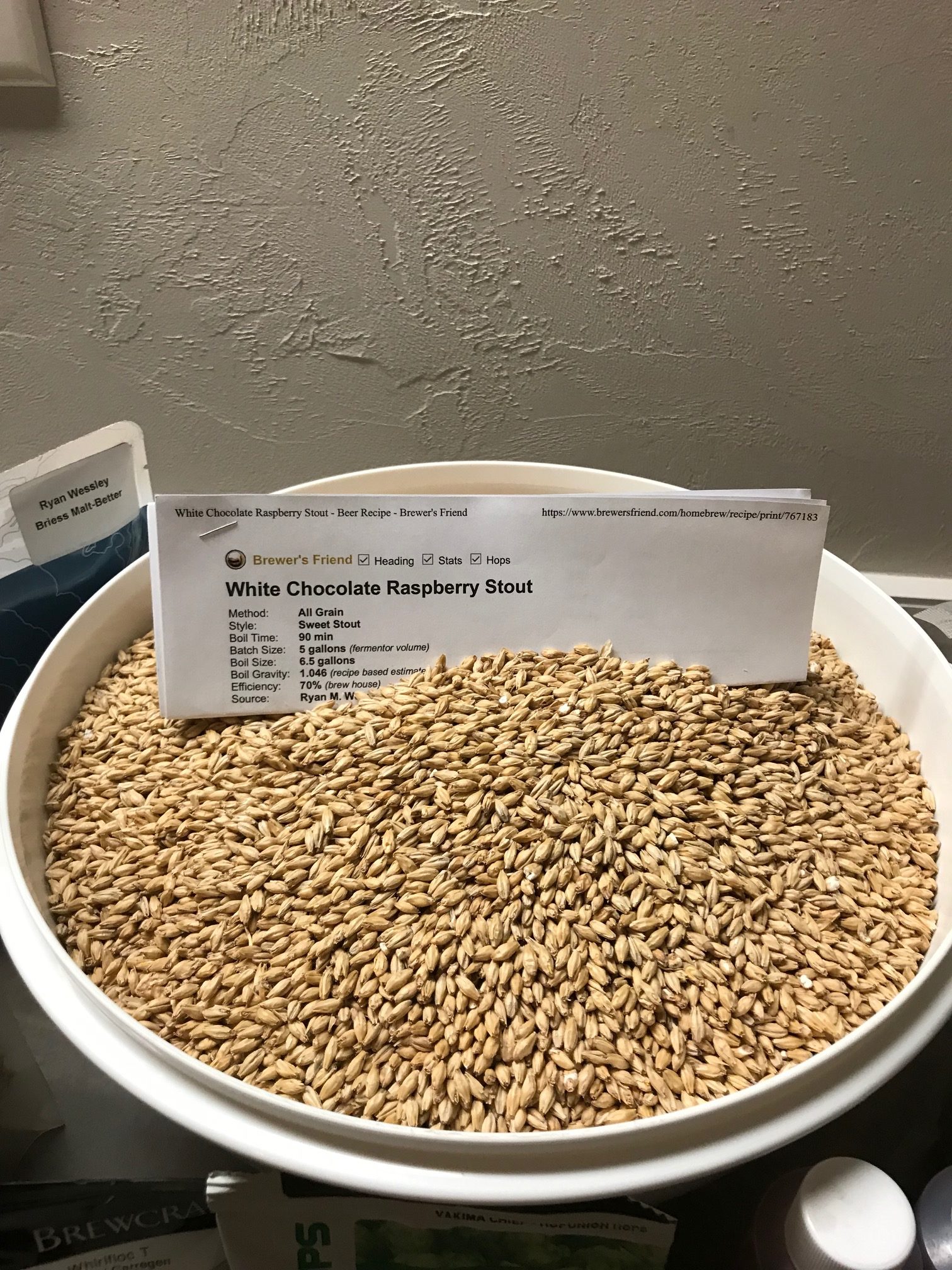

During the last two days in January, I had the wonderful experience of visiting the Briess Barley Operations in Northwest Wyoming. This was my first visit to our barley elevator in Ralston and seed plant in Powell. I journeyed to Wyoming simply expecting to see a dozen gigantic bins and a large seed cleaning system. What I found was that and something much more memorable; an impressive culture of quality and a world-class group of Briess employees.

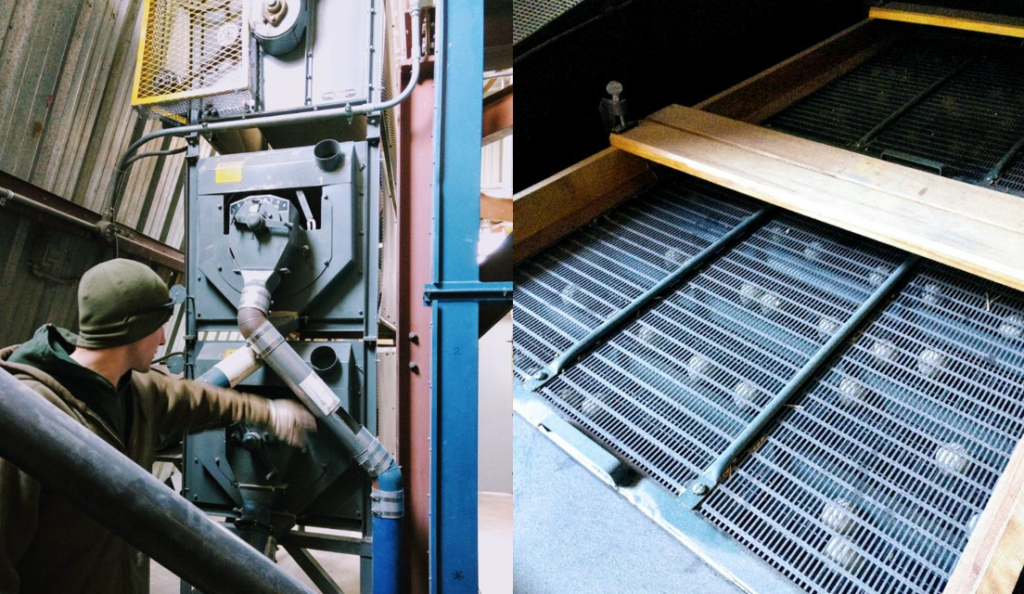

On day one, Betsy Roberts (Quality Manager of Malting) and I met up with Rick, Cameron, Kenny and Brad to tour the seed plant. Barley seed is both cleaned and treated at this location. Cleaning promotes uniformity in the size of the barley kernels, which encourages uniform growth in the field. Most maltsters have the first opportunity to control their own quality when their barley is received at the malthouse; we have the added benefit of controlling our quality before the seed is ever even planted in the ground.

On day two, Betsy and I were joined by Bob Hansen (Manager of Technical Services) for a tour of the Ralston Barley Elevator. We had the immensely good fortune of staying on-site at the Briess cabin, which provided breathtaking views.

Once we arrived at the barley elevator, Judy and Tammy led us through a tour of the barley quality laboratory. During the busy harvest season, these women are joined by a few seasonal employees who help them process a seemingly endless flow of barley trucks. An exterior robotic arm allows the technicians to remotely sample barley from each incoming truck and vacuum transport it into the lab. Judy told us about a fun tradition they have of inviting children of the growers to operate this robotic arm and sample their own family’s barley. Even in the busy chaos of the harvest season, Judy and Tammy take the time to demonstrate how much they truly care for our grower community.

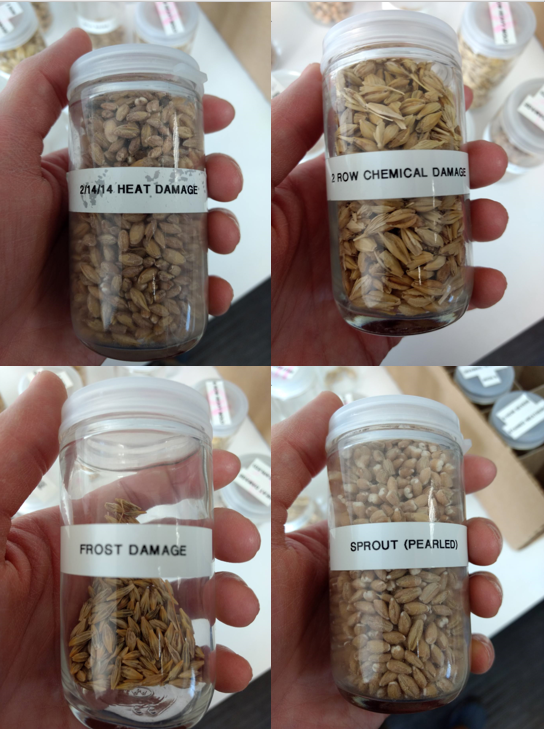

I was in awe of the expertise that Judy and Tammy bring to Briess. Whether the barley is accepted or rejected is entirely up to them and their highly trained seasonal staff. Judy showed me a library of barley defect training samples that displayed various forms of disease and damage. She has an impressive ability to quickly identify quality defects and confidently determine if the barley should be accepted for malting quality, feed quality, or rejected altogether.

In the afternoon, we met up with Rick to tour the barley elevator. Knowing that the elevator was “large” did not prepare me for the overwhelming size of the bins, especially when we walked inside an empty one. Each bin is equipped with floor-to-ceiling temperature sensors and an airflow system. Barley that has been loaded from the field is warm — and if not actively cooled, it will remain warm throughout the storage season. It is very important to keep the barley cool and dry, so insect life cycles are not promoted and the barley will maintain high malting quality. Please reach out to us if you have questions about the growing, cleaning, or transportation process.