It’s a tough road for barley to audition for its big debut in the Malthouse. After what could be a varied growing season, which may include factors from untimely rains to prolonged droughts, the barley that reaches maturity is harvested and delivered to the Briess Barley Operations elevator in Ralston, WY. At this point, the barley reaches its first audition to reach the malthouse. Raw barley is tested on specific requirements in factors such as plumpness, moisture, protein, insect infestation, blight, mold, mycotoxins, skinned & broken kernels, as well as damage from pre-harvest sprout, insect, heat, or frost. Not meeting the requirements of any one of these factors will disqualify barley as suitable for malting.

For the barley that makes the cut, the journey continues. Traveling via rail, it makes its way to the Briess Malt Operations elevator in Manitowoc, WI. However, the barley is not quite yet ready to dive into the steep tanks and become fantastic malt. The barley must first undergo the “dirty dance” of being cleaned and graded in preparation for the malting process. Three distinct stages of the barley cleaning process take place at the Briess Elevator, including the following:

1. Separation of material by width

2. Separation of material by length

3. Grading of the clean barley

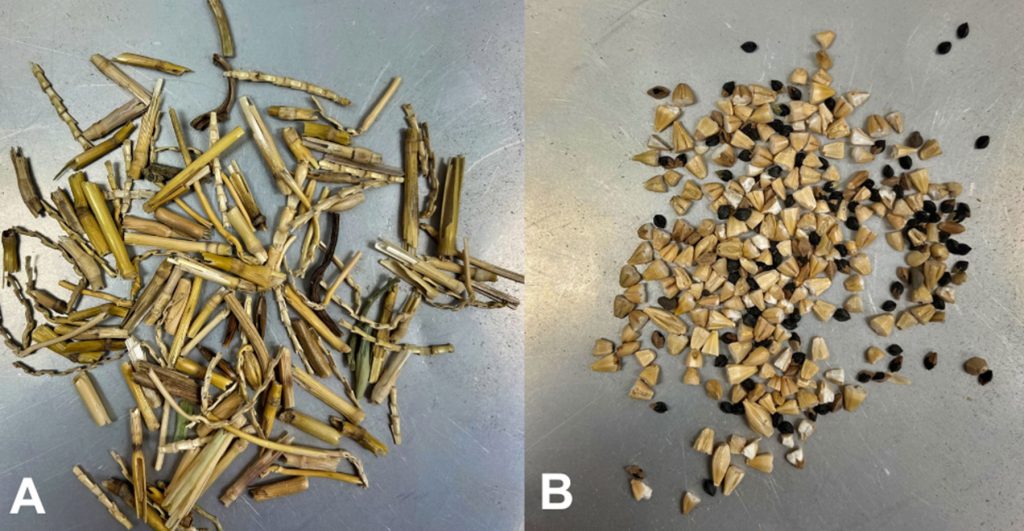

The first stage of cleaning, which is the separation of material by width, removes the bulk of material that is unwanted in the malting process. Undesirable material includes both excess large plant debris from the field as well as fine dust and chaff. This process is performed by dispersing barley over a series of shaking slotted trays of varied width. The first trays in the series are slotted larger than the width of a barley kernel. This process is also known as grain scalping, which allows the barley to fall through the slots while materials, such as barley straw or flower heads from field weeds, remain on the tray and continue to travel to a byproduct path.

Following the scalping trays, barley is dispersed across secondary sifting trays slotted narrower than the width of a barley kernel. These allow barley to travel across the top of the tray to its next destination while the smaller chaff, dust, and weed seeds fall through and onto a byproduct pathway.

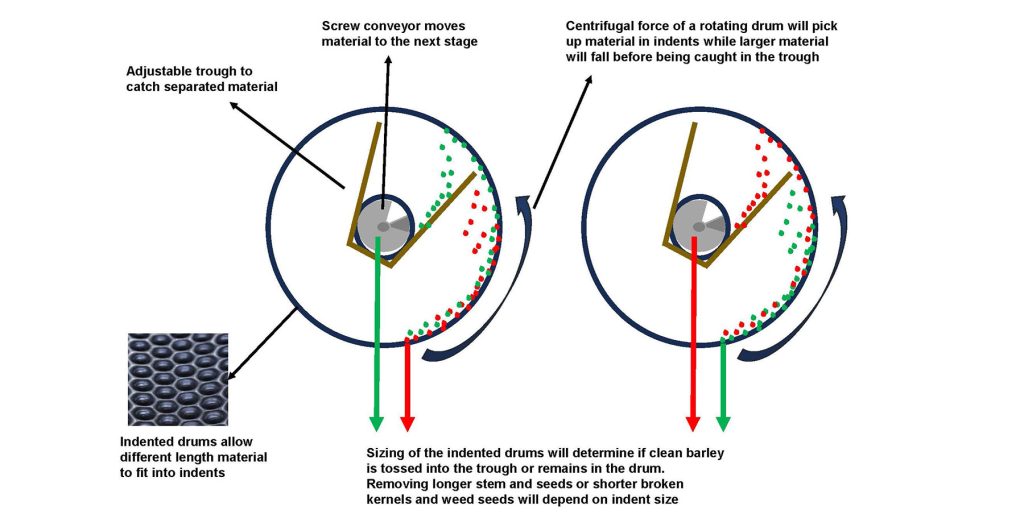

The second stage for barley cleaning is the separation of material by length. While the first stage of cleaning was able to remove material that has a width different from barley, foreign material that is similar in width will remain in the product. The use of indented cylinder separators achieves the removal of remaining foreign material by separating it by length. Indented cylinder separators are large rotating drums that have thousands of indents on the interior walls. Based on the size of the indent, the material passing through is picked up during the rotation of the drum and will drop at different points in the cycle. Adjusting a trough in the middle of the drum at different points will capture and segregate different materials as they drop. The adjustments of the trough and sizing of the indents will determine what is being removed. Material longer than barley, such as stems and large weed seeds, or material shorter than barley, such as broken kernels or small weed seeds.

The third and final stage of the cleaning process is not a cleaning step, but a sorting of the barley kernels by size, also known as grading. The size of the barley kernel has an influence on critical factors, such as water uptake, protein content, enzymatic power, and extract values. Both malthouse recipes and end-use malt created will change based on what grade of barley is used. As an example, the larger plump grades of A & B will be used for kilned base malts, whereas the thinner high enzyme grades of C & D are better suited for distilling malts. The grading of barley Is achieved in the same way as the first step of the cleaning process, where shaking trays with different-sized slots will allow kernels of one size to pass through while the others remain on top of the tray.

The clean and graded barley has finally completed its dirty dance and is ready for the malthouse. Following malting, the malt will see two more steps of cleaning prior to reaching our customers. After the final kilning of the malt, a kiln cleaning step will remove dried sprout material and excess chaff. Prior to shipment or packaging, we also remove any final dust or chaff that may have been created during the movement of the malt.