“Variety’s the very spice of life,

WILLIAM COWPER

that gives it all its flavor”

As brewers of craft-y beers we relish in the ingredient variety available to us; dozens of kilned and roasted malts, hundreds of yeast and hop varieties, not to mention all the other grains, woods, fruits, sugars, herbs, bacteria, pickles, and chili peppers we frequently cram into our cherished vessels of self-expression. Yes, brewing can be wonderfully spicy with variety, but it can also be frustrating if we don’t fully understand the ingredients. Take wheat for example; there are several different forms that are often interchangeable as if they are equivalent, but each form will impart distinct characteristics and performance to your brewing. This article will explore differences in wheat brewing ingredients and how you might expect them to perform in your brewery.

Red vs. White Wheat

The two major classifications of wheat variety are Red Wheat and White Wheat. This article will focus on Red Wheat only. If you prefer working with White Wheat, don’t worry, product differences described below will hold true for White Wheat products as well.

Sensory (Red Wheat)

- Raw Wheat – wheat flour flavor, typically <1.0 SRM

- Torrified Wheat – very slightly nutty flavor, typically 1.5 SRM

- Flaked Wheat – slightly nutty flavor, typically 2.0 SRM

- Malted Wheat – full flavor, sweet, malty, wheat flour, typically 3.0 SRM

Extract Yield

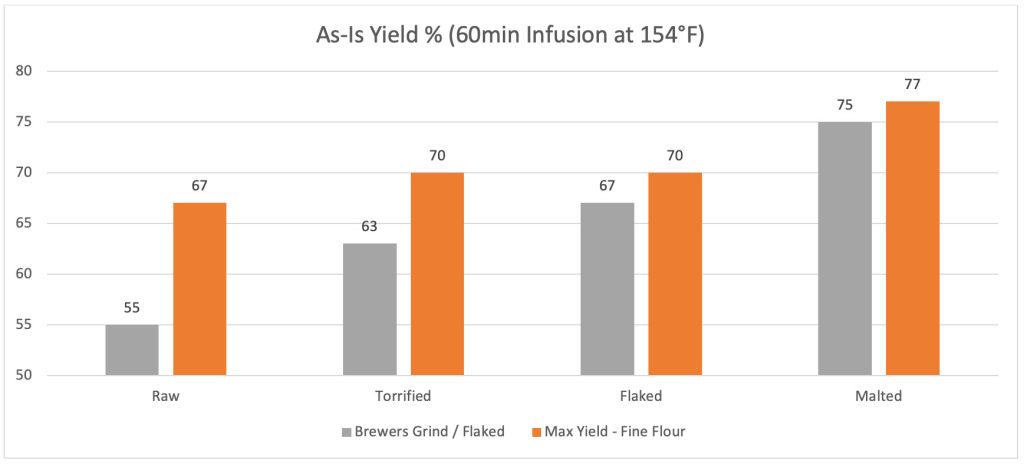

- Raw Wheat – The raw seeds’ starches are firmly bound within the raw endosperm of the kernel, which inhibits the enzymes’ ability to access the starches. The degree of milling will have a large effect on the ease at which extract can be recovered; coarsely ground grits will show about 20% lower extract efficiency compared to finely ground flour (see chart below). Even as fine flour, raw wheat has less extract potential than a torrified or flaked product due to higher moisture content. You may want to bump the inclusion rate up if using this in place of a flaked or torrified product.

- Torrified Wheat – Torrefaction, a heating process like popping popcorn, causes disruption of the raw endosperm structure breaking down the internal starch binding structure of the kernel to make starches more available to enzymatic breakdown and extraction (See Image 1). Because the starch structure has been partially disrupted, the degree of milling is not as important as in raw wheat but will still have an impact on extract efficiency.

- Flaked Wheat – Immediately after torrefaction, the wheat passes through a specialized mill that squishes and elongates the grain making the starch highly accessible for mashing. It does not require milling; even in an unagitated infusion mash, it can be expected to give a good extract yield as a flake.

- Malted Wheat – Malting is a several days process where enzymes will dismantle the starch binding structure, liberating most of the starch and solubilizing proteins in the process. The typical extract values and maximum extract values will be greater than other forms of wheat discussed due to the magic of malting. It is not necessary to finely grind malted wheat to obtain excellent extract efficiency.

Processability

| Raw Wheat | Can be difficult to mill because the raw structure is quite hard. Lauters well when properly milled to a typical brewers grind. Use rice hulls at high inclusion rates. |

| Torrified Wheat | Easy to mill due to its brittle nature. Lauters well when properly milled to a typical brewers grind. Use rice hulls at high inclusion rates. |

| Flaked Wheat | No need to mill this product, lauters well at moderate usage rates but can be doughy and may slow lauters above 20% inclusion rates. |

| Malted Wheat | Easy to mill, very friable, good extract even with coarse grinds. Lauters well when properly milled to a typical brewers grind. Use rice hulls at high inclusion rates. |

When to Use

| Raw Wheat | Use when you want a grainy raw wheat character with little color in an adjunct brew (suggest up to 50%). |

| Torrified Wheat | Use when you are looking for a clean wheat character with good yield at low-to-high inclusion rates (suggest up to 50%). |

| Flaked Wheat | Use when you are looking for a clean wheat character with excellent extract yield at a moderate inclusion rate (suggest up to 20%). |

| Malted Wheat | Use when you are looking to add maltiness to your beer (suggest up to 70%). |

I hope you find this article informative in determining how to use these little ‘Spices of Life’ in your future brewing.