Congratulations to Deb and Dan Carey who founded their well-known Wisconsin craft brewery, New Glarus Brewing Co., 20 years ago this year! Earlier this summer I went to congratulate them in person, and ended up being treated to a thorough tour of their new brewery, and getting a first-hand look at their current building projects. There’s no shortage of those.

Perched high on a hill just south of New Glarus, Wis., the 115,000-square-foot brewery can be seen from miles away. The Carey’s have been brewing here for almost six years, and also brew at their original location just a couple miles away.

This is an impressive destination brewery designed for efficiency, expansion, and a great visitor experience. The buildings and landscaping resemble a Wisconsin dairy farm with touches of Bavaria and Switzerland. And I love the “ruins” of an old brewery that is being re-created on the hill behind the brewery—complete with six tap handles connected directly to tanks inside the brewery!

One of the current projects is the addition of five bright tanks and 15 fermentation tanks which will increase current production of 145,000 bbl to a total of 250,000 bbl annually. The tank farm is going in a new, second red barn. “Where else do you keep Spotted Cow?” Dan asked. This expansion follows the addition last year of a 17,000-sq-ft warehouse. Another is scheduled next year.

Visitors walk past copper kettles, literally miles of stainless steel piping, up to open fermentation tanks, and into packaging where a bottling line turns out 300 bottles per minute and 65 cases per hour. Very impressive is the smallest footprint kegging robotic in the world the staff affectionately call “Cow Tipper” (check out the videos below!).

Environmental stewardship plays a huge role in operations, and they produce 1.2 bbl of beer per therm. That’s efficient. Dan also said that New Glarus Brewing Co. was recently accepted into the State of Wisconsin’s Green Tier program. The program partners businesses with the DNR to further increase efficiencies and decrease emissions. Only a handful of Wisconsin breweries have applied and been accepted into it.

Dan explained how a Steineker Stromboli wort boiling system contributes to the brewery’s efficiency and efficient use of resources. In fact, New Glarus uses less than 3.6 barrels of water to produce each barrel of beer. That’s efficient.

The Stromboli system ties into a closed heat exchange system that reverts hot water and steam to re-usable water. Some of the wastewater this is discharged from the brewery is diverted to the nearby hop garden. Ammonia refrigeration systems are also used.

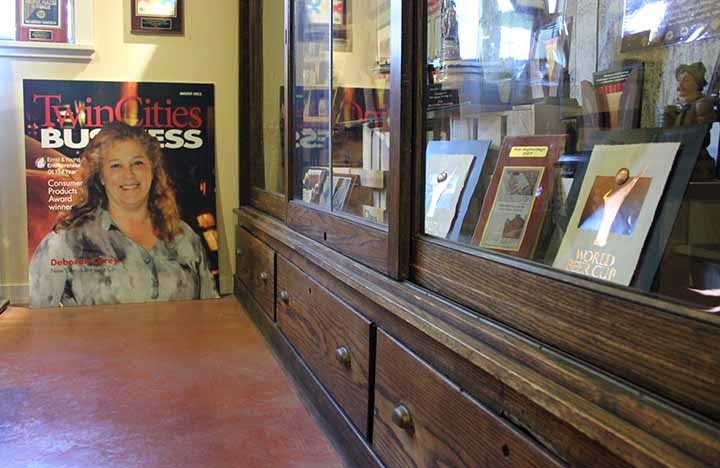

Having different and clearly split responsibilities is the secret to Dan and Deb successfully working together over the years. Deb handles business operations and marketing, while Dan is the head brewmaster and focuses on brewing. Key to their success, he pointed out, is a dedicated employee base.

Daily operations are split between three managers. Scott Noll oversees raw materials from procurement to packaging and focuses on ways to be more lean and efficient. Assistant master brewer Jean Hengstl focuses on fermentation and brewing. And brewer Randy Thiel, former Ommegang brewer, handles R&D and special projects.

Scott toured me thru most of the brewery before Dan was available. An eight-year Army veteran, he obviously enjoys his work and working at New Glarus. He spoke highly about the Carey’s and how well employees are treated.

Employees are encouraged to “work smarter, not harder”, he told me. And Deb and Dan’s creative approach to business and never-ending projects are exciting, which he described “like running a marathon at a sprint”. Equally exciting is that the current round of projects will help free up time for training and other activities.

During the tour, Scott pointed out many parts of the brewery that were built with expansion in mind. One example was the pilot brewery that Scott said Dan had designed specifically to scale up to the brewery. “He wants to build something that goes beyond him,” Scott told me.

Getting such a close look at New Glarus Brewing Co. was a wonderful experience, and thanks again to Dan, Deb, and the whole crew who spent time with me. And congratulations again to the Carey’s!