As craft brewing and distilling continue to evolve, wheat has become a more highly utilized grain. Known for its ability to contribute haze, add clean sweetness and body, among other flavor contributions, wheat is a grain that requires its own set of special circumstances in the malthouse to produce a functional and flavorful finished product. When selecting an appropriate wheat variety for malting use, there is some overlap in critical quality parameters between malting and milling.

Some Shared Quality Parameters between malting and milling:

- Soundness: No evidence of Pre-Harvest Sprout, which directly affects the germination potential of wheat for malting use, and the alpha-amylase content of wheat for milling use.

- Moisture: Low moisture content to prevent mold during storage, typically <14.5%. Grains at harvest in either industry are typically not used right away, so they need to be removed from fields and stored in stable form.

- Test Weight: Higher test weight is always desired, as it translates to more yield per lb. of raw material.

- Mycotoxins: Levels within FDA regulations.

Conversely, there are some quality factors that are different between milling and malting use:

- Protein

- Milling – High protein is desired in some wheat as it translates to better dough performance.

- Malting – Lower protein is desired as it translates to higher extract potential and beer yield. The correlation of total protein content to soluble protein content is an ongoing evaluation for a maltster, as the accessibility of those proteins may not be the same as barley.

- Dormancy

- Milling – Lack of any alpha-amylase activity at harvest and prior to use is critical for most baking applications of wheat, as it can affect dough structure.

- Malting – Lack of alpha-amylase activity at harvest is critical for malting use as it affects the long-term germination potential of wheat, but the ability of a grain to break dormancy is critical to timing of use in production and recipe development to fit within a standard malting timeframe.

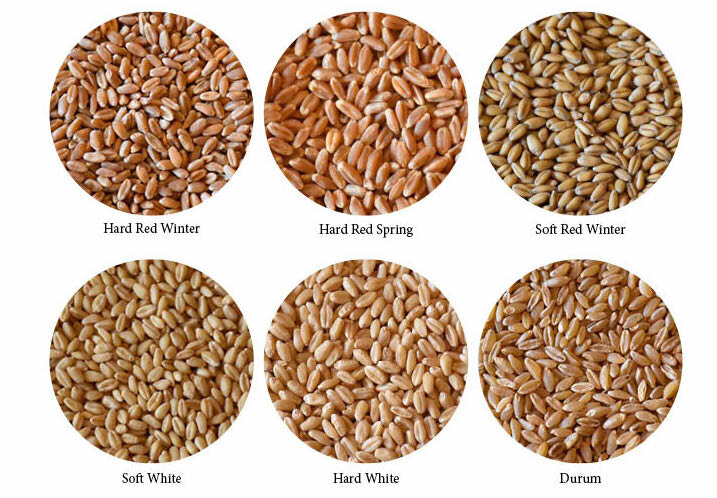

There are six classes of wheat that are grown throughout the U.S., which are defined by the following categories:

Photo Credit: National Agriculture in the Classroom

| Vitreousness | Bran Color | Planting Date |

|---|---|---|

| Hard | Red | Winter |

| Soft | White | Spring |

| Durum |

The meaning of each of these categories is defined by the following:

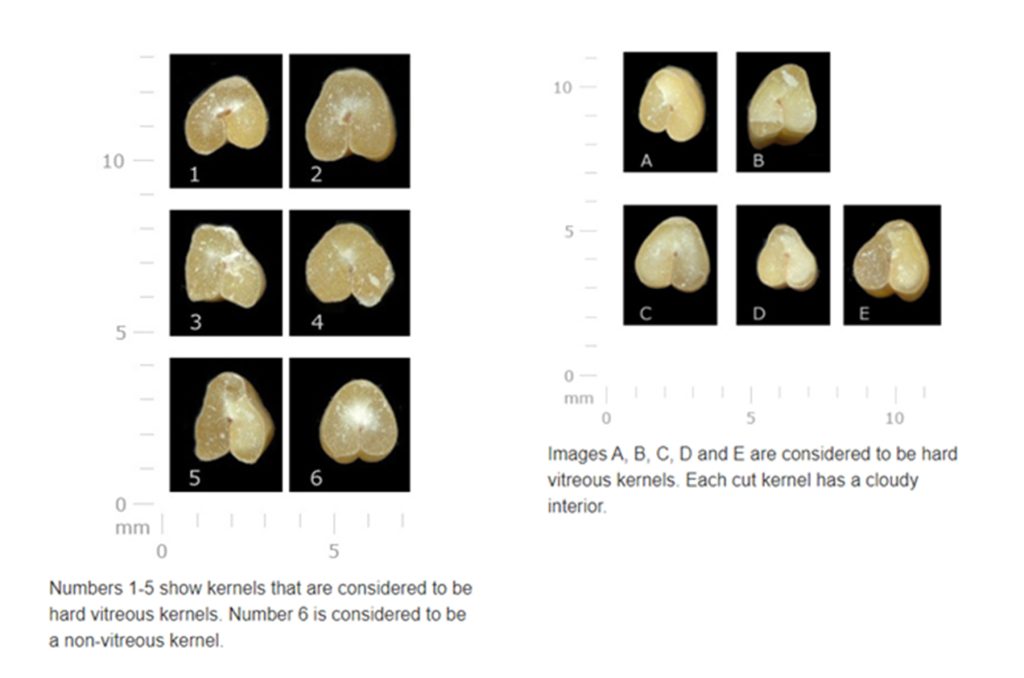

- Vitreousness: an optical property that is measured optically by the degree of opaque vs. starchy and correlated to the protein content. This is an important measure in wheat milling as it can translate to ease of milling, yield, and end-use.

- Maltster Perspective: degree of vitreousness would affect how a kernel will hydrate and is considered when developing the malting recipe.

Photo Credit: Canadian Grain Commission

- Bran Color: the visual comparison of the external appearance of an intact kernel and is classified as red or white. Red wheat has a reddish hue to the outer bran layer and may have a higher level of phenolic compounds that contribute to the hue, which in traditional baking use can contribute nuttier flavor. White wheat has a more beige outer bran layer and may contribute a cleaner and sweeter finished flavor. In milling and baking, the selection of red vs. white wheat aligns more directly with the end application.

- Maltster Perspective: The impact of the bran color does not affect hydration and growth but can have an impact in how we develop kilning recipes related to the finished sensory targets of each.

- Planting Date: the time of year for planting, which directly impacts agronomic inputs, growth cycle, and harvest timing. The region in which the wheat is being planted is the largest influence on the variety of wheat selected for planting. Winter wheat is typically planted in the fall and bred to have a level of dormancy to allow it to remain quiescent in the ground until the conditions are right to initiate growth. Given the typically earlier growth initiation, maturation and harvest timing is typically weeks earlier than spring-planted wheat. Spring wheat is planted, as its name indicates, in the spring, and is harvested in late summer to early autumn.

- Maltster Perspective: Planting date has a similar influence on wheat as we see with barley bred for and planted in winter vs. spring, with the primary difference being dormancy levels. Dormancy for malting use needs to fall within a range of enough to prevent pre-harvest sprouting, but not too much that we are unable to malt until months after harvest. Winter varieties generally have higher levels of dormancy than spring, but the level is dependent on genetics and environmental factors.

Malting wheat presents its own set of unique challenges. Unlike the role played by the American Malting Barley Association (AMBA), in the support and definition of Malting Barley Varieties, wheat does not have a malting industry equivalent. Briess has worked closely with our wheat suppliers to optimize and select the varieties that offer the best agronomics, malting performance, and functional performance for our customers. Our offerings of Red Wheat Malt and White Wheat Malt offers distinctive functional and flavor characteristics that can fit a wide range of use. We continue to research and evaluate new wheat varieties that will enhance our wheat malt offerings.