An excerpt from “Grind Profiles for Optimum Distilling Yields“

Many distillers that distill on grain may be missing an opportunity to optimize their distillery’s yield by not utilizing the correct grind for their raw ingredients. In 2012 in conjunction with Dr. Kris Berglund at MSU, Briess evaluated and quantified the difference in yield between preground malt and floured malt.

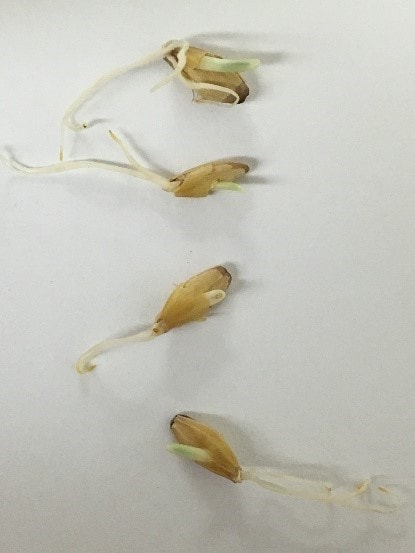

There are several mills to select from when grinding malt. Commonly used in the brewing industry is a 4-roller Mill. This produces a very coarse, non-uniform grind that consists of slightly cracked and crushed kernels. This grind profile is ideal for a distiller using a lautering process to separate the solids from the liquid prior to going to the still. Adjustments to this milling process can be made through changing the size of the gaps between the rollers. . .

Read the full article on “Grind profiles for Optimum Distilling Yields” here.