This year I was fortunate enough to join the growing ranks of Hop & Brew School alum. This two-day, hop-infused workshop at Hopunion in Yakima was definitely worth the travel time, even the flight delay coming home! Our good friends there know hops and hospitality! If you ever have the chance to attend, I highly recommend it. If you’ve already been there, you probably have your favorite takeaways. Here are mine, but not in any particular order.

#1 – The Aroma. Every workday I’m greeted at the front door by the sweet aroma of malt. Yeah, I know, that’s not a bad gig. In Yakima I was greeted by the aroma of hops the minute we descended the Cascade Mountain Range into the Yakima Valley. At least it seemed like it. The hop harvest was underway, making it the perfect time to be there, and literally everywhere we went hop aroma permeated the air. This put everyone in our group of 140, mostly brewers, in some kind of hop-induced trance. You can almost smell the hops in this video of a hop kiln being filled.

#2 – The People. Camaraderie is an endearing quality of the American craft beer community, and Hop School proved the perfect setting to renew old friendships, make new ones and network. Special thanks to Hopunion’s Melody and Bree for letting me pick their brains about their school. Several years ago Briess started its own two-day Malt & Brew Workshop, which has been extremely well received. But there’s always room for improvement, and I unashamedly snitch good ideas when I uncover them.

#3 – The Program. It seemed like the entire staff at Hopunion worked the event, which was very well orchestrated. There were tours, presentations, food and entertainment. New this year, according to Melody, was a 1-1/2 hour sensory session. Very impressive.

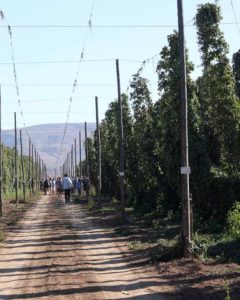

#4 – The Harvest. A definite highlight was a visit to a Loftus Ranches field being harvested. Empty trucks waited in line to be filled with hops, then beat it back to the ranch for processing and return to the field.

#5 – The Growers. These are wonderful people who opened their farms and fields to us. Most hop farms have been family operated for generations. The evening before school started found us at the Perrault Hop Farm for a grower’s party, which our class was invited to for food, beer and music. The next day we returned to visit some of their experimental hop fields.

#6 – The Process. After harvest the vines and cones are separated then kiln dried at the grower’s farm. At Loftus Ranches, the process is conducted inside a large barn then the cones are conveyed to the kiln in another building. Packing cones into 200-pound bales occurs in a third building.

The Perrault Hop Farm recently underwent a complete renovation which included the addition of new equipment they patented that very efficiently separates vines and cones.

#7 – Hopunion. There’s a lot to see here including pelletizing, packaging and cold storage. Under one roof are offices, the pilot brewery a tasting room, an indoor/outdoor area dedicated to sensory and hop selection, and a well-known social area lined with blackboards that visitors have been signing for years.

#8 – Beer. There was plenty of it, which provided this malt-bomb lover the opp to step outside of my beer comfort zone.

#9 – Beer. Did I say beer? After watching harvest, we stopped for a panel discussion and beer at Bale Breaker Brewing Co., which is nicely nestled between acres of hops fields. Very nice!

And last but not least…

#10 – Cascade Mountains. We took the scenic route back to Seattle, where I took this parting shot of Mount Rainier. Absolutely gorgeous!