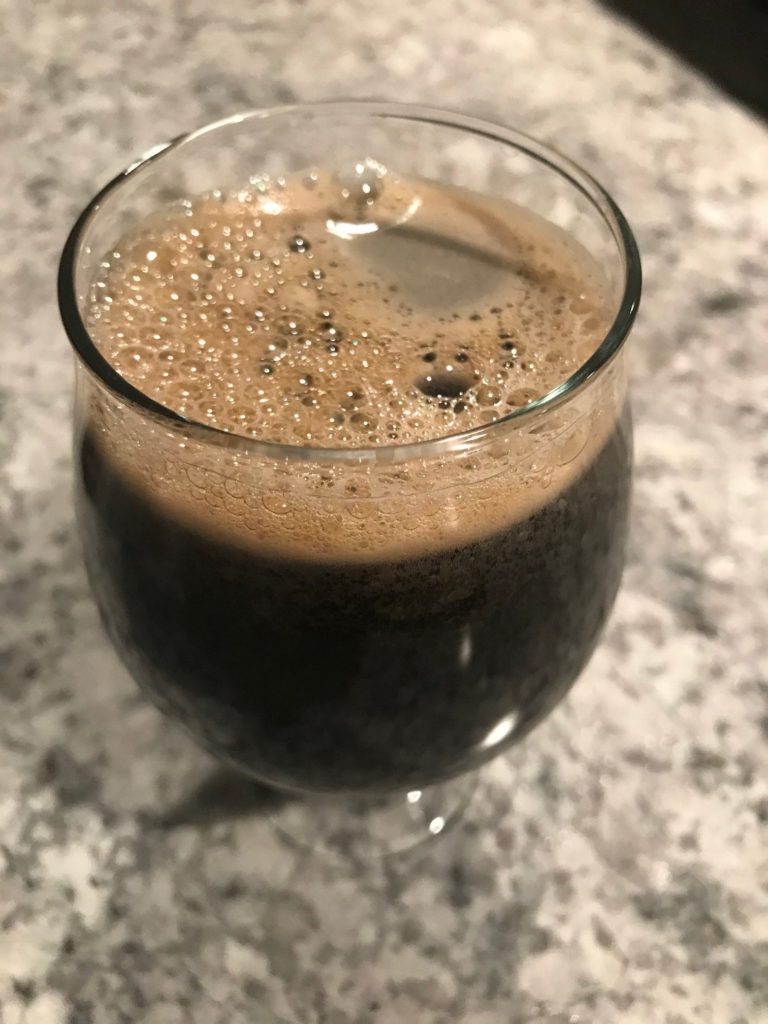

Oatmeal Stout is a sub-style of stout, the main distinction being the inclusion of up to 20% oat (flakes in this homebrew) by weight in the grist.

Oat flakes are a cereal grain with high concentrations — relative to barley — as body-enhancing beta-glucans, water-soluble lipids, and proteins. These all add up to a bountiful, silky, and palate-coating mouthfeel in the beer. Oatmeal stouts tend to be sweeter than their counterpart dry stouts, but trend towards being less sweet than sweet or milk stouts.

This kit is offered from one of our regional distributors, More Flavor www.moreflavor.com. The kit is 100% all-grain and was a joy to brew, so pony up by the fire and enjoy this sweet and silky homebrew.

The recipe is for 5 U.S. gallons (19L).

- OG: 1.072

- FG: 1.021

- ABV: 6.6%

- IBU: 40

- (SRM): 35

QUANTITY/INGREDIENTS

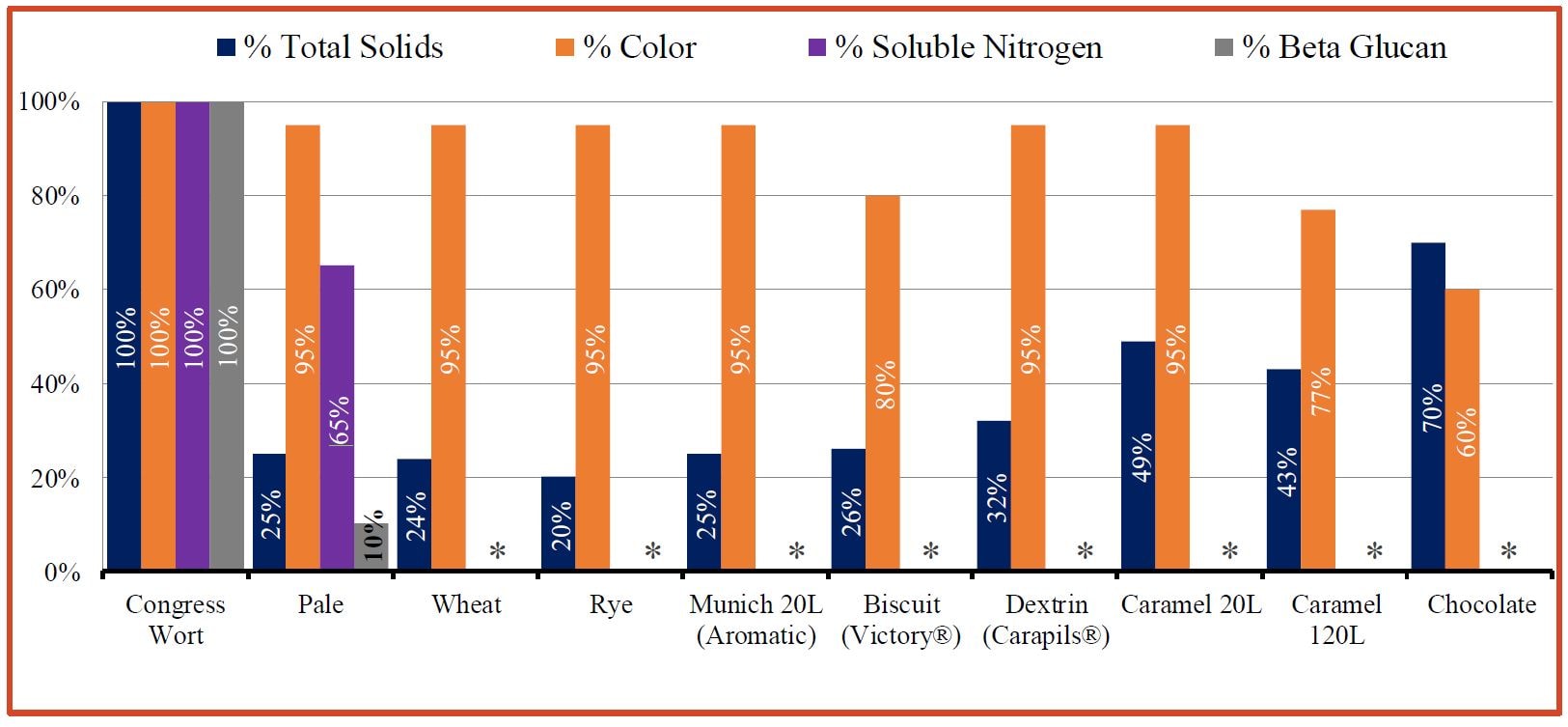

- 10 lbs Briess 2-Row Pale Ale

- 1 lb Briess Flaked Oats

- 8 oz. Briess Caramel 120L

- 8 oz. Briess Black Roasted Barley

- 8 oz. Briess Chocolate Malt

- 4 oz. Briess Black Prinz®

- 4 oz. Briess White Wheat

- 4 oz. Briess Carapils®

- 2 oz. Chinook Hops

- 2 oz. Cashmere Hops

- Wyeast: 1968 London ESB

- 1 oz. Clarifier

- (1) Grain Steeping Bag (optional)

BREWING PROCEDURE

Mashing: Pour at least 6.5 gallons of water into the brew vessel and heat until it reaches 165°F. While water is heating, add the grains slowly while stirring. Continue stirring for a few minutes after the grain has been added to make sure that the entire mash is a consistent temperature and that all dough balls have been eliminated. Letting the mash sit for 60 minutes at 148-160°F will result in full enzymatic conversion of the starches to sugars.

Recirculation: A little step in between mashing and sparging that helps to clear up the runoff from the mash. Recirculate the wort by removing some from the spigot below the false bottom and add it back to the top of the grain bed. Do this until the runoff is nearly free of visible debris, then you can start to sparge.

Sparging: Begin the process by opening the Hot Liquor tank valve and allow the water to flow onto the grain bed. A stationary sparge arm is a time- saving addition for this process if you have one handy. Connect a piece of tubing onto the ball valve on the mash tun and allow it to run into the boil kettle. Open the valve on the bottom of the mash tun to allow wort to flow out of the mash tun and into the boil kettle. Keep at least a two-inch layer of water on top of the grain bed to keep incoming sparge water from channeling through the grain. We recommend a slow sparge, usually taking 45-60 minutes to ensure that there is plenty of time for the sugars to rinse out.

Boil: Add 2oz. Chinook hops at boil for 60 minutes. Add 2oz. Cashmere last 5 minutes of boil. Add 1 oz. Clarifier last 5 minutes of boil.

Cool the wort as quickly as possible by placing it in an ice bath. Temperature must be below 100°F before it is safe for yeast. Put a lid on the brew vessel while it cools to avoid contamination.

While the wort is cooling, sanitize the fermenting equipment (fermenter, lid, rubber stopper, thermometer, airlock, etc.), along with the yeast pack and a pair of scissors.

Once wort cools down to 100°F or lower, transfer to the fermenter. Leave residue in the bottom of the brew vessel. You may have to use a funnel at this point if your fermenter is a carboy.

Aerate the wort by sealing the fermenter and rocking back and forth for a few minutes. Use sanitized scissors to open the yeast pack and add yeast to the wort. Seal your fermenter. Add water to the airlock (until it reaches the fill line) and insert into the stopper.

Let your beer ferment for 2 weeks in a cool (72°F or lower) dark place.

FERMENTATION Fermentation activity will last between 12-72 hours after adding the yeast. A krausen (kroy-ZEN) layer will develop on the top layer during fermentation. After 72 hours, fermentation will slow down, the krausen layer will subside and activity will be minimal the remainder of these 2 weeks.

Optional — transfer to secondary fermenter. Sanitize siphoning equipment, airlock, carboy bung, and stopper. Siphon the beer from the primary fermenter into the secondary. If you do not have a secondary fermenter, simply leave the beer in the primary fermenter.

Secondary Fermentation — Optional. Allow the beer to condition in the secondary fermenter for 2 weeks before proceeding with the next step.

- Sanitize siphoning and bottling/kegging equipment.

- Mix a priming solution (a measured amount of sugar dissolved in water to carbonate the bottled beer). Use the following amounts, depending on which type of sugar you use:

- Corn Sugar (dextrose) 2/3 cup in 10 oz. water

- Table Sugar (sucrose) 5/8 cup in 16 oz. water

- Bring the solution and pour into the bottling bucket

- Siphon beer into bottling bucket and mix with priming solution. Stir gently to mix — don’t splash.

- Fill and cap bottles.

- Kegging — fill beer from fermenter into keg — pressurize as you see fit and enjoy!