There’s an old saying, that “It all starts as beer and it all starts clear.” Distillers are a creative bunch, and it is common to see distilleries that have started with a standard configuration and modify it to fit the needs of their operation or the desired flavor of the spirit. Yep, there is all sorts of gear out there. Having said that, there are some distillery configurations that have stood the test of time and comprise the majority of what is used today to produce world-class spirits.

These still types distill-wash beer, wine, or a slightly thicker fermented-grain bourbon wash. These fermented washes are typically between 7-11% alcohol by volume (ABV). All the configurations, with the skill of the distiller knowing when to make the heads, hearts, and tail cuts, determine the flavor of the spirit. The hearts are separated out and used for the final product. Often, the heart cuts of several distilling runs are mingled to create “new-make spirit.” It’s this blend that is barreled. The heads and tails are safely discarded, recycled into the next distillation, or used in non-consumable products.

Configurations and Components: All of the distilling systems below have a heat source to heat the wash to drive out all the alcohols as a vapor. They all utilize condensers to condense the alcohol vapors into a liquid.

- Pot Stills: Pot stills are the oldest configuration type. Pot stills are a batch process and often used in making all-malt Scotch Whisky, Mezcal, Brandy, Dark Rum, and Irish Whiskey. As an example, the kit used to make Scotch whiskey includes a mash tun with false bottom, washback (fermenter), a wash still to produce a rough initial separation of alcohol called low wines, a Spirit still used to increase the alcohol level of the low wines into spirit, and a spirit safe. The Spirit Safe is used by the distiller to separate the alcohol fractions pulled off during distillation: heads, hearts, and tails. This configuration also has a condenser to bring the alcohol from gas phase to liquid phase. Generally, traditional Scotch whisky uses a “lautered wash” where the mash tun is used to strain out the wort from the mash much like in the beer industry. The wash is fermented in about 72 hours and then distilled. The classic Pot Wash still and Spirit still are slower and offer less efficient separation than a Column still; they do, however, give a more complex congener profile (flavor components) to the final spirit. After the initial wash distillation, the final spirit is generally around 25% ABV. The Spirit still is used to further separate out the desirable flavor and aroma compounds and to bring the final spirit up to around 75% ABV. The inefficiency of this system is largely due to increased stillhouse residency time associated with two distillations, increased energy usage, and imperfect separation of congeners which decreases overall yield. Distillers on these systems will trade flavor for efficiency all day.

The 40‘ Continuous Column still at Breckenridge Distillery, Breckenridge CO. - Continuous Column Stills: As the name implies, these stills are designed to be fed wash on a continuous basis and produce a high alcohol content spirit at the end of two column sections that purify the spirit while working in a loop that uses live steam to power the process. Continuous columns work by performing the wash distillation and spirit distillation we saw in the Pot still in one single pass. The continuous column is divided into two sections: the stripping column (or analyzer) for rough alcohol separation from the fed wash, and the rectifying section used for fine separation of ethanol and other congeners. Each section is composed of a series of plates, shown in the photo below. As the vapor moves up the column each plate acts as its own small distillation unit, continuously driving the alcohol content higher. The distiller can manipulate the character of the product by adjusting which plate the spirit is pulled from before heading to the condenser. These are high throughput, high alcohol content units primarily used for producing neutral spirits destined for products like vodka and gin. These columns require less downtime for cleaning than a classic Pot still set up. They are the true workhorses in the grain neutral spirits industry.

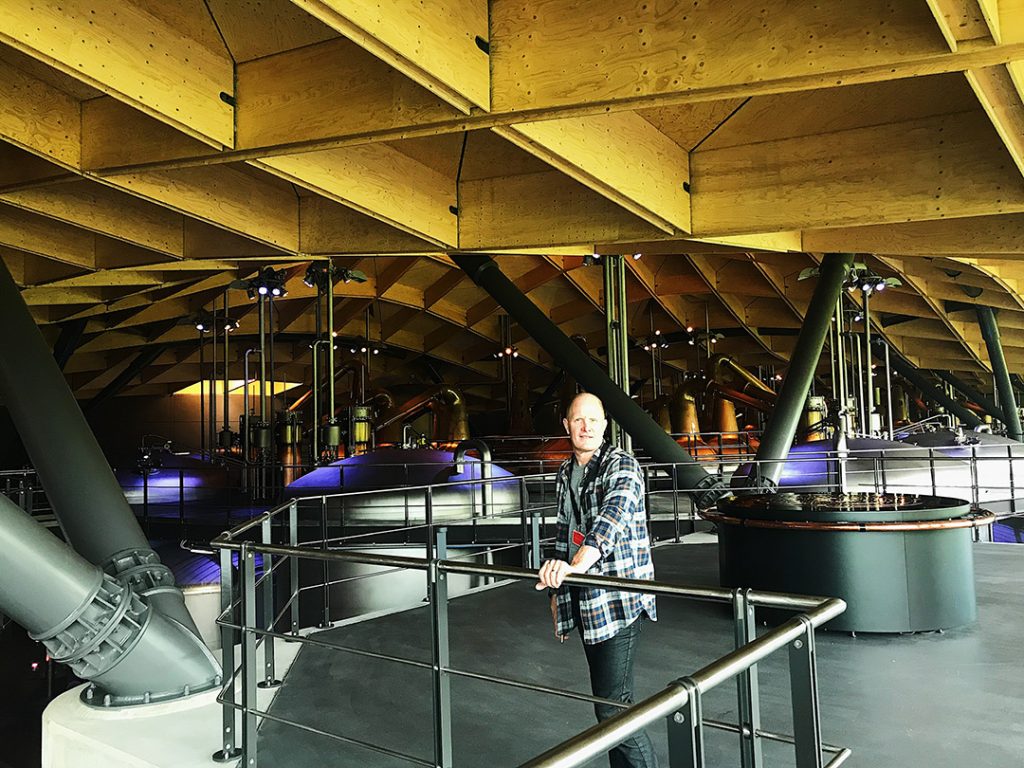

Stainless steel washbacks and still sets at Macallan Distillery in Craigellachie, Moray, Scotland. - Hybrid Stills: A Hybrid pot design is favored by many craft distillers. By combining the benefits of a Pot still and a Column still, maximum flexibility can be achieved. Typically, the entire fermented mash goes into the still; this is known as “distilling on grain.” The columns in these stills operate in the same way as continuous columns, by driving up the alcohol content, however each plate can generally be turned on or off allowing the distiller to manipulate the character of their spirit with more or less separation of congeners.

Well, there you have it, a peek at the beer and clear side of whiskey/whiskey making. The rest is left to the creative use of new and used barrels and allowing time to do its thing. I’m looking forward to sharing a beer or a dram with you all soon.

Cheers,

Dan