Crystal Red™ is an innovative, new roaster-produced crystal malt. A product from years of effort, this specially produced crystal malt has been made to be the most intense source of red color available on the market. With an average color of 200 SRM, this malt is almost twice as intense as its nearest offering from Briess – our Caramel 120L. It’s so effective as a coloring malt, that we’ve deviated from our normal caramel malt nomenclature and named it after its purpose: Crystal Red.

Crystal Red can be used to make extremely red beers or to simply bump the color of lighter-colored beers like IPAs or Pale Ales to a bit more golden with minimal flavor impact. When trying to formulate low-alcohol or no-alcohol beers, it’s great at providing expected color with limited addition to total extract. Additionally, at higher levels, Crystal Red can be used to provide complex dark sugar flavor notes to various darker styles, such as Stouts and Belgian Ales.

To better understand how crystal malt is used, let’s look closer at the effects that crystal malts have on beer and how Crystal Red fits into this spectrum. Let’s open the “Crystal Malt User’s Manual” and examine how crystal malts are used to affect the color, flavor, acidity, body, and residual extract in beer.

Color

First, let’s understand how crystal malts affect beer color. The answer is simple – they all do it the same way, they just do it more or less. That is, they all contribute the same type of coloring compounds. Darker crystal malts simply have more of them, and Crystal Red has the most. We’ve written about and published papers on this before, which you can see in the posts below:

Defining wort colors: red malts vs black malts

Predicting Beer Color Based on Formulation

Achieving a particular Yellow (3-5 SRM), Orange (5-15 SRM), Red (15-30 SRM) to Mahoghany to Brown (30 SRM +), is simply a matter of doing the math and picking the crystal and kilned malt you want based on what else you want to come with it, that is whatever flavors or other characteristics.

Now, that’s a bit of a qualified statement, that if you really want a dark red to mahogany color (30 SRM), you have to use a dark caramel. It’s simply not possible to make a 30 SRM beer with a 10L caramel malt; the math doesn’t work. When we say that dark caramels are used to make red and mahogany tones, it’s not that the color they contribute is different, it’s just that to get to that intense red color, you need to use an intensely colored malt. You can see from the below picture, the color contributed by different caramel malts at a standard usage rate of 50% in a hot steep.

Flavor

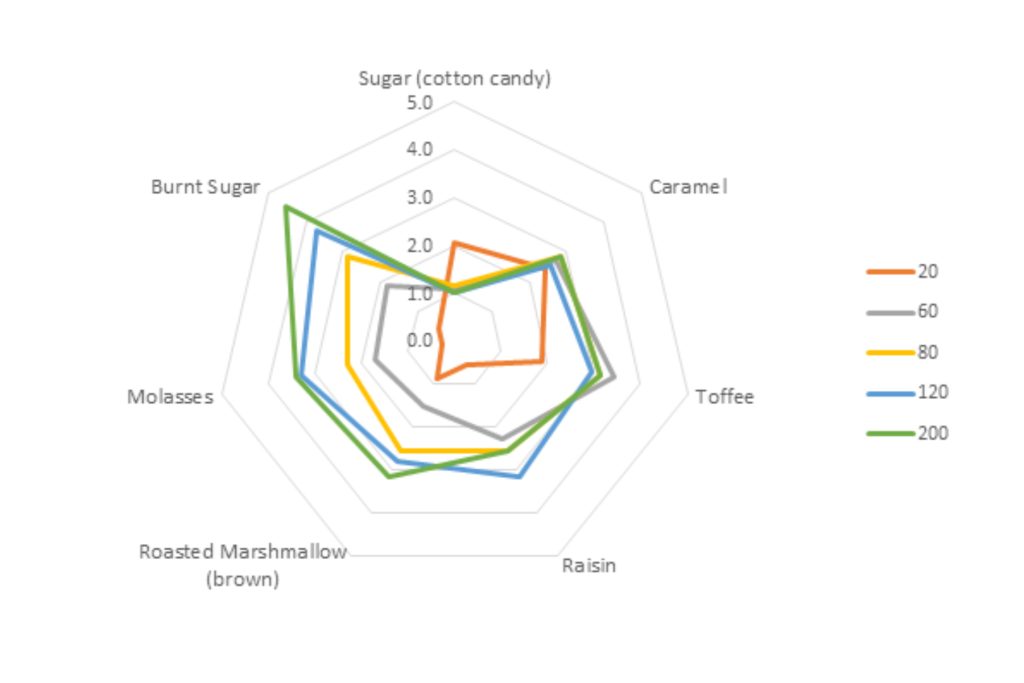

Along with color, crystal malts are also used for the flavors they impart to beer. As the sugars are caramelized in the roaster, they develop flavors. As the degree of caramelization increases, the flavor intensity increases, and the types of flavors change from “light” cooked sugar flavors, like Caramel, to “darker” flavors, like Roasted Marshmallow. You can see this in the graph below where the flavor and flavor intensity are evaluated against each other using the hot steep method with the standard 50% usage of crystal malt. Note how the lightest crystal malt has the least complex and least intense flavor and the darkest crystals have strong burnt sugar notes.

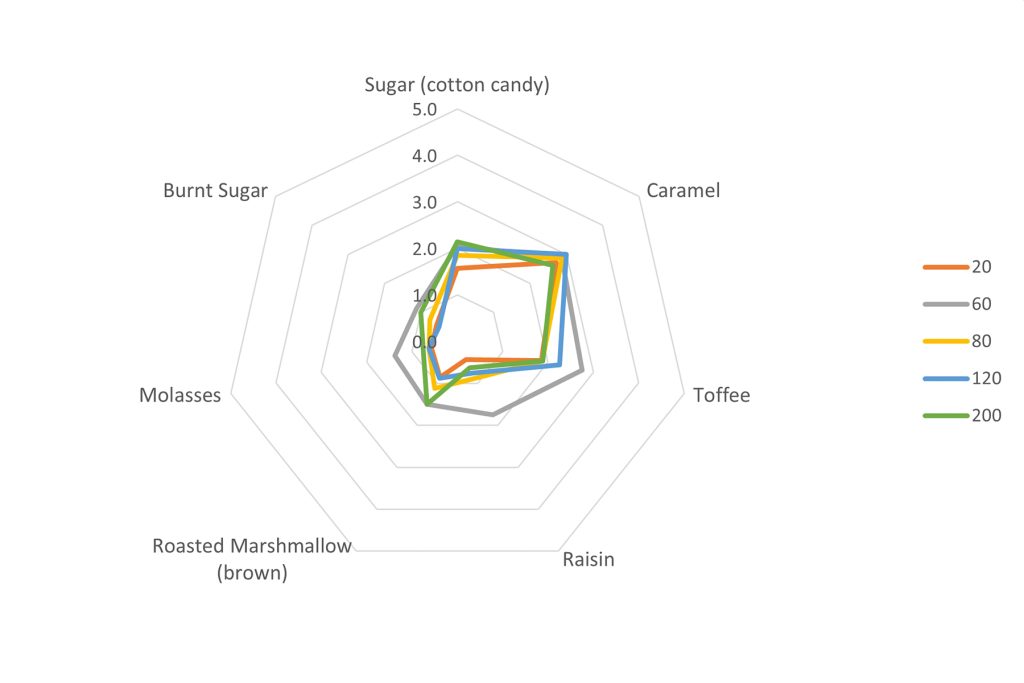

When formulating with crystal malts, it’s important to understand these flavors and their intensity vary based on usage rate. Imagine you want to get Raisin and complex dark sugar notes in your beer. Obviously, from the chart, you can see that you won’t get those from a light crystal malt, even if you use it at 50%. You will need to use a dark crystal malt. Does that mean that you always get burnt sugar notes from dark crystal malt? Well, not necessarily. Let’s consider the flavors that you PRACTICALLY get when using crystal malts for color. The below graph shows worts formulated using the hot steep method where different crystal malts were used to add 10 SRM of color. Keep in mind, the usage of Crystal Red is 1/10th the usage of Caramel 20L.

Notice that the flavor contribution is very similar. If the charts had error bars, then these results would be almost identical. Of significance, Caramel 60 drives more intermediate sugar flavors like Toffee and Raisin at this usage rate. Crystal Red is less flavorful than C60 at this usage rate and overall, the same as the other caramel malts, with a slight increase in Roasted Marshmallow. The flavor differences are only subtlety different for different caramel malts at this usage rate and all flavors are slight to moderate (1-3 on the intensity rating scale).

When using a crystal malt for flavor, it’s important to understand the flavors that are present and then use them at the amount needed to drive them. Moderate Raisin, Roasted Marshmallow, or Burnt Sugar notes are only achieved when using a darker crystal malt AND using them at a larger usage rate. Practically they don’t become that noticeable until you get the beer color above 10 SRM.

Acidity and pH

A variety of acidic compounds are generated by Maillard and caramelization reactions during the roasting of crystal malt. Not surprisingly, the amount of these acids increases with increasing color of the roast. Dark roasted crystal malts can be as acidic as black roasted malts, and their impact on mash pH is observable. Consider the chart below that looks at the pH of Congress mashes using different percentages of crystal malt. Standard Congress mash usages of 50% are mostly unheard of in beer formulation, so we’ve included more realistic usage rates of 25%, 10%, and then a variable usage rate that will create a standardized color of 11 SRM (corresponding to 50% for C20 to 5% for Crystal Red).

| CONGRESS MASH pH | ||||

| Usage-> | 50% | 25% | 10% | 11 SRM |

| Caramel 20 | 5.48 | 5.56 | 5.62 | 5.48 |

| Caramel 60 | 5.46 | 5.59 | ||

| Caramel 80 | 5.34 | 5.58 | ||

| Caramel 120 | 5.28 | 5.64 | ||

| Crystal Red | 5.18 | 5.26 | 5.51 | 5.65 |

Though darker crystal malts are more acidic, they have a lower acidity/color ratio than lower-color caramels. Thus, practically, darker caramels contribute less acidity at the same color than lighter caramels, and at 11 SRM, Crystal Red has the least acidic mash (table above).

The organic acids in crystal malt are weak acids and they are somewhat volatilized, metabolized, or scrubbed in brewing and fermentation and don’t, therefore, significantly affect (the much lower) finished beer pH at practical usage rates.

Body, Mouthfeel, and Residual Extract

Because they don’t go through a long, warm kilning process, and the additional modification that occurs, crystal malts can have more large molecular weight proteins and non-starch polysaccharides. Additionally, sugars in the kernel, which would normally become fermentable extract, are polymerized or reacted by caramelization and Maillard reactions into unfermentable compounds. For these reasons, the extract of crystal malts is fundamentally different from that of normal kilned base malts. These complex molecules increase the body and mouthfeel of the finished beer. In large amounts (>10%), they will slightly increase finished beer viscosity and may lead to reduced filtration time.

Crystal malts can give increased body and reduced fermentability, but these effects really depend on caramel type and usage rate. The extract of crystal malts can be 10% (lighter) – 25% (darker) less fermentable than base malts. Though this is a significant percentage, because of normal usage rates, the effect is normally small. Consider that a 10% usage rate of low-color caramel would only reduce real fermentability by 1%. A dark caramel malt at this usage rate would be a more significant 2.5%, but this would be limited to dark beers by design. Reduced fermentability increases by a factor of 2.5 (10%-25%) across the caramel malt spectrum, but color, with Crystal Red, increases by a factor of 20. Thus, on an equal color basis, the dark crystals actually result in more fermentable worts than lighter caramels. Additionally, on an equal color basis, darker malts contribute less body and mouthfeel.

Crystal malts are devoid of enzymes and behave like adjuncts in the mashing process. This can also affect the degree of fermentability of a mash. Some have used low-color caramels, moderate enzyme base malt, and high-temperature, short-time mashing to produce mashes, with limited conversion, and worts of low fermentability.

Summary

Why are there so many different types of crystal malts? They each make a unique contribution to beer. Used appropriately, they generate unique types of flavors, non-fermentables, body, mouthfeel, acidity, and color. The spectrum of crystal malts allows for flexibility in formulation. Want caramel and light sugar flavors without burnt sugar notes and a lot of color? Use generous amounts of lower caramel with a percentage of high caramel for a color boost. Want a little red color boost with minimal flavor, body, or effect? Use a small amount of Crystal Red. Want some sweet sugar notes, some body, and a little color? Use a low-color crystal malt.

Drinkability and excellence in beer in our highly competitive marketplace are based on proper formulation and execution. Truly understanding crystal malts is part of this equation. Crystal Red represents a unique solution to some of these formulation challenges and bookends an important position in the pallet of malt.

Featured below are some recipes the Briess Technical Services Team created to demonstrate the Crystal Red impact and how other caramel malts can be used to create excellent beers.

The story behind the Buzzing the Tower beer label goes back to our National Sales Meeting in February, which was “Top Gun” themed and where Crystal Red malt was first introduced in a beer for our Division Sales Managers to taste in a finished product. If you remember the “Buzzing the Tower” scene from the movie, you’ll understand the fighter jet imagery that we placed above the Manitowoc River near our Malthouse. Notice the falcons? Of course, we had to include some of those iconic birds of prey, which are born in the nesting box on one of Briess’ elevators every year.

Buzzing the Tower (Brewhouse Recipe)

Caramel sweetness and a soft molasses aroma are balanced with a drying finish using Briess Crystal Red Malt.

- OG: 1.052

- FG: 1.013

- ABV: 5.0%

- IBU: 20

- COLOR (SRM): 26

| QUANTITY | INGREDIENTS | COMMENT |

| 56% | Briess Synergy Select Pilsen Malt | |

| 30% | Briess Pale Ale Malt | |

| 7% | Briess Crystal Red Malt | |

| 7% | Briess Caramel Malt 30L | |

| 20 IBU | Perle Hops | 60 min boil |

| Irish Ale Yeast | Fermenter |

Buzzing the Tower (Homebrew Recipe)

Caramel sweetness and a soft molasses aroma are balanced with a drying finish using Briess Crystal Red Malt.

- OG: 1.052

- FG: 1.013

- ABV: 5.0%

- IBU: 20

- COLOR (SRM): 26

| QUANTITY | INGREDIENTS | COMMENT |

| 5.6# / 5-gal | Briess Synergy Select Pilsen Malt | |

| 3.0# / 5-gal | Briess Pale Ale Malt | |

| 0.7# / 5-gal | Briess Crystal Red Malt | |

| 0.7# / 5-gal | Briess Caramel Malt 30L | |

| 1.0 oz / 5-gal | Perle Hops | 60 min boil |

| Irish Ale Yeast | Fermenter |

All Red, All Red, All Red! Pale Ale (Brewhouse Recipe)

American Pale Ale formulated to showcase the intense red color that can be achieved using Briess Crystal Red Malt.

- OG: 1.058

- FG: 1.015

- ABV: 5.0%

- IBU: 45

- COLOR (SRM): 17

| QUANTITY | INGREDIENTS | COMMENT |

| 63.5% | Briess Synergy Select Pilsen Malt | |

| 33% | Briess Pale Ale Malt | |

| 3.5% | Briess Crystal Red Malt | |

| 2 – 4 oz / bbl | Cascade Hops | 60 min boil |

| 2 – 4 oz / bbl | Centennial Hops | 60 min boil |

| 4 oz / bbl | Cascade Hops | 15 min boil |

| 4 oz / bbl | Centennial Hops | 15 min boil |

| 8 oz / bbl | Cascade Hops | 1 min boil |

| 8 oz / bbl | Centennial Hops | 1 min boil |

| 8 oz / bbl | Cascade Hops | Dry Hop in Secondary |

| 8 oz / bbl | Centennial Hops | Dry Hop in Secondary |

| American Ale Yeast | Fermenter | |

All Red, All Red, All Red! Pale Ale (Homebrew Recipe)

American Pale Ale formulated to showcase the intense red color that can be achieved using Briess Crystal Red Malt.

- OG: 1.058

- FG: 1.015

- ABV: 5.0%

- IBU: 45

- COLOR (SRM): 17

| QUANTITY | INGREDIENTS | COMMENT |

| 7.1# / 5-gal | Briess Synergy Select Pilsen Malt | |

| 3.7# / 5-gal | Briess Pale Ale Malt | |

| 0.4# / 5-gal | Briess Crystal Red Malt | |

| 0.5 oz / 5-gal | Cascade Hops | 60 min boil |

| 0.5 oz / 5-gal | Centennial Hop | 60 min boil |

| 0.7 oz / 5-gal | Cascade Hops | 15 min boil |

| 0.7 oz / 5-gal | Centennial Hops | 15 min boil |

| 1.5 oz / 5-gal | Cascade Hops | 1 min boil |

| 1.5 oz / 5-gal | Centennial Hops | 1 min boil |

| 1.5 oz / 5-gal | Cascade Hops | Dry Hop in Secondary |

| 1.5 oz / 5-gal | Centennial Hops | Dry Hop in Secondary |

| American Ale Yeast | Fermenter |