Our innovative new brewing ingredient, MaltGems® is now available for sampling and ordering! By custom milling our Synergy Select Pilsen Malt,

we removed the majority of husk to create a malt that eliminates the bitter, astringent flavors common with other base malts. What remains is MaltGems® — the Heart of the Malt — that delivers exceptional performance and lautering due to the removal of fine grit, flour, and water-binding husk. MaltGems® can be used in any beer style where clean, sweet, well-rounded base malt flavor is desired and is exclusively available from Briess. Expect balanced flavor with subtle bread, cracker, and honey notes along with a remarkably clean finish only achieved by eliminating husk-based polyphenols. Read on for technical details and a sample recipe.

This is what Synergy Select Pilsen looks like before being put through our customized milling process…

This is MaltGems® …

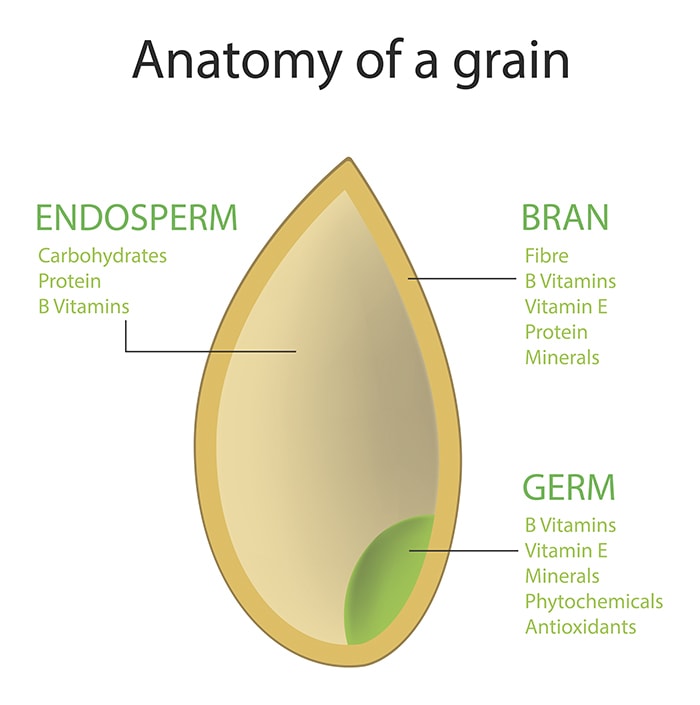

Endosperm brewing with MaltGems® is a great way to create an extremely clean beer without the bitter husk flavors that traditional base malts can impart. But what is endosperm? It is the starchy middle of a barley kernel that functions as an energy source for the growing seed. This starch is bound in a matrix of protein and polysaccharides which require enzymatic modification (malting) to make the starch readily accessible during mashing. Sugars and protein fragments created in this modification interact during kilning to produce the malt’s signature color and flavor. The endosperm is where most of the extract, color, and flavor reside.

Husk and sprouting portions of the malt are not considered endosperm. Husks contain tannic polyphenols that can contribute harshness to the finish of beer, a characteristic some beer consumers have become accustomed to. Acrospires are the sprouted portions of the malt that make their way into finished malt; these contain an elevated level of bitter peptides, which we have also become used to.

By removing the majority of husk and acrospires, Briess has created a product that can easily be used to create endosperm brewed beers. By also removing the flour and fine grits, MaltGems® can be lautered without the need to add any of the husks back. Coarse, endosperm-rich grits lauter well because the fine materials that can cause doughiness have been removed. One additional benefit of removing husk is that it frees up a lot of mash water; husk tends to soak up water like a sponge (about 4x as much as the endosperm). Without the husks, brewers can process higher grist loads (20% higher) and make higher gravity worts. For further details, please view our CBC presentation. If you’re interested in giving MaltGems® a try, the clean, sweet flavor vs. a standard base malt is particularly notable in the Helles recipe below.

MaltGems® Helles Lager Recipe 10BBL

Grist and Hops

- 500 lbs of Synergy Select Pilsen MaltGems®

- 100 mL of lactic acid (88%)

- 0.9 lbs of Magnum, 14.1% alpha-acids

- 2.6 lbs Mittelfrüh 4.0%AA

- 1.4 lbs Hersbrucker, 3.0%AA

- 1.4 lbs Tettnanger, 2.5%AA

Yeast (one of the following)

- White Labs: German Bock Yeast WLP833

- Wyeast: Hella-Bock Yeast 2487

- Omega: German Bock OYL-111

- BSI: German Lager 3 BSI-833

Process

- Add 100 mL of lactic acid (88%) to brewing water

- Mash in 500 lbs of Synergy Select Pilsen MaltGems® at 120°F

- Mash at 144°F for 45 minutes

- Mash at 157°F for 30 min

- Lauter at 157°F

- Vorlauf to obtain semi-clear wort

- Sparge to obtain 12.5 Plato at knock-out

- Bring to boil, add 60 min hops (0.9 lbs of Magnum, 14.1% alpha-acids)

- Boil 45 min

- Add 15 min hops (1.3 lbs Mittelfrüh 4.0%AA, 0.7 lbs Hersbrucker, 3.0%AA, & 0.7 lbs Tettnanger, 2.5%AA)

- Boil 10 min

- Add 5 min hops (1.3 lbs Mittelfrüh 4.0%AA, 0.7 lbs Hersbrucker, 3.0%AA, & 0.7 lbs Tettnanger, 2.5%AA)

- Boil 5 min

- Whirlpool

- Transfer to fermenter at 52°F, aggressively aerate wort during transfer (~8 ppm of oxygen)

- Pitch 19 million cells/mL of wort (1.5 million cells/mL/P)

Fermentation

- Primary ~2 weeks at 52°F

- Diacetyl rest 3 days at 60°F (~1.015 specific gravity)

- Secondary 4–6 weeks at 32–36°F (~1.011 specific gravity)

- Carbonate to 6.0 g/L of CO2 (3.1 volumes of CO2)

Stats

- Original gravity 1.050

- Final gravity 1.011

- Alcohol by weight 4.2%

- Alcohol by volume 5.2%

- IBU 16

- SRM 3

- pH 4.3